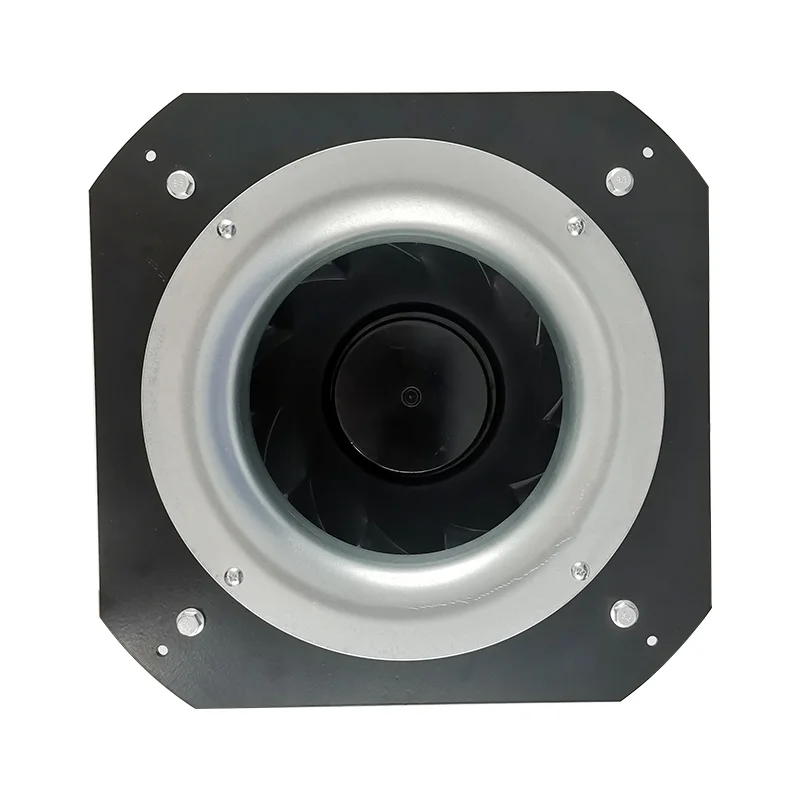

Deixe-me perguntar: você já viu um ventilador centrífugo reverso? Este tipo de ventilador funciona de maneira diferente dos outros ventiladores. Seu uso é bastante comum na indústria, como para tornar o trabalho mais rápido e seguro. O ventilador recebe esse nome devido à forma como opera. No centro de sua estrutura, uma pás de impulso gira, movimentando o ar em rotação. Isso, por sua vez, leva à expulsão do ar sendo expelido longe do movimento da pás.

As características que os ventiladores centrífugos utilizados em locais industriais proporcionam são essas grandes vantagens competitivas. Antes de tudo, esses ventiladores são excelentes na limpeza do ar em um espaço. Eles proporcionam um ambiente de trabalho melhor e mais seguro ao remover rapidamente partículas nocivas como poeira, poluentes. Além disso, eles ajudam a minimizar o risco de incêndio ou explosão que pode ser causado por substâncias inflamáveis, especialmente entre aqueles que trabalham com tais materiais.

Os ventiladores centrífugos retrógrados evoluíram ao longo dos anos, abrangendo muitas melhorias e adições. A parte mais importante, que é responsável pelo movimento de ar - a pás ou rotor - foi revisada. Nos dias de hoje, rotores modernos são feitos de materiais leves que os tornam eficientes em seu desempenho. Além disso, o desenvolvimento contínuo do motor que impulsiona esse rotor significa mais potência e maior confiabilidade também. Portanto, ao escolher um ventilador para requisitos específicos, deve-se incluir a seleção do motor correto, pois é isso que regula a velocidade de funcionamento do ventilador. Além disso, as melhorias no design e nos materiais da carcaça do ventilador são uma contribuição significativa. Agora, ela é composta por uma construção mais forte e durável, tanto para o rotor quanto para o motor. Novos materiais mais leves e resistentes à corrosão ajudaram a prolongar a vida útil das instalações.

Pode ser uma tarefa intimidadora escolher o ventilador centrífugo perfeito para uso industrial. Pontos-chave a considerar são o tamanho do espaço que precisa ser ventilado ou resfriado, quanto ar é necessário e o que há nele. Se você deseja obter a classificação correta de CFM (pés cúbicos por minuto) para um ventilador, uma das primeiras coisas necessárias é calcular quantos pés cúbicos aquele espaço tem. Além disso, o fluxo de ar também deve atender ao propósito para o qual o ventilador será empregado. Se você o estiver usando em uma oficina, o ventilador terá que trabalhar mais do que quando usado dentro de casa, pois uma área maior precisa ser resfriada e, portanto, mais volume de ar em qualquer momento dado. Importante, o ventilador selecionado deve ser compatível com os elementos encontrados no ar; se houver substâncias inflamáveis sendo processadas, é necessária uma construção à prova de explosão junto com materiais resistentes a faíscas. O último recurso importante a ser verificado é o nível de ruído do ventilador, pois ele precisa operar em níveis de decibéis mais baixos se for utilizado em configurações que exigem desempenho silencioso. Escolha um ventilador de baixa vibração para ajudar a proteger o compressor de ar e limitar a transmissão de vibração para equipamentos ou estruturas próximas.

Atualmente, ventiladores centrífugos para trás são usados em muitos tipos de indústrias e é um dos ventiladores com ampla aplicação. A aplicação mais comum de ventiladores industriais está no setor de HVAC, que significa aquecimento, ventilação e ar condicionado, onde esses ventiladores desempenham um papel primário na circulação de ar dentro dos prédios, além de ajudar a controlar as temperaturas internas. Esses ventiladores desempenham um papel crucial na fornecimento de ar fresco e ventilação em minas subterrâneas para o setor de mineração. Na área automotiva, eles são usados para resfriar uma grande quantidade de equipamentos e para gestão de temperatura nas fábricas. Além disso, a comunidade médica depende desses ventiladores para garantir a ausência de germes e manter a esterilidade em salas limpas, além de proteção contra contaminação.

Finalmente, com a discussão acima, era ambíguo por que ventiladores centrífugos reversos eram complexos, mas atualmente eles ocupam uma posição importante nas indústrias recentes. Eles são ventiladores eficientes e econômicos que melhoram significativamente a qualidade do ar e a segurança, frequentemente necessários para manter a produtividade em espaços industriais. Entender como eles funcionam e quais fatores importantes considerar ao escolher o certo ajudará você a tomar uma decisão informada que pode resultar no crescimento do seu negócio também no futuro.

somos um fabricante profissional e podemos fornecer motores e ventiladores de todos os níveis a custos muito competitivos. Oferecemos ventiladores CA, motores EC e ventiladores CC. Novos produtos estão atualmente em desenvolvimento. A empresa também colabora com especialistas de instituições de ensino superior para o desenvolvimento de ventiladores centrífugos reversos e novos ventiladores.

Somos capazes de aceitar pedidos com base em amostras fornecidas pelos clientes, especificando detalhes, projeto e embalagem de ventiladores centrífugos reversos. Prestamos o melhor serviço pós-venda. Permaneceremos fiéis ao nosso conceito central de negócios: Integridade, Qualidade, Inovação e Ganha-Ganha. Comprometemo-nos a desenvolver uma estratégia operacional da marca "Hangyan" e a formar características de serviço excelentes e economicamente vantajosas. Colaboramos com nossos clientes por meio de nossa abordagem prática e do trabalho em equipe sincero para construir um futuro melhor.

empresa fundada em 1996. A área de produção da empresa é de até 30.000 metros quadrados e está equipada com 11 oficinas. Somos um fabricante reconhecido, especializado na pesquisa e desenvolvimento de diversos tipos de ventiladores de rotor externo e motores de corrente contínua. Contamos com mais de 100 funcionários, mais de 6 linhas de produção e mais de 25 anos de experiência em ventiladores centrífugos reversos.

A equipe de P&D possui vasta experiência e alta qualidade. Os padrões de qualidade são muito rigorosos. Utilizamos a norma ISO 9001:2015 como padrão de produção; os produtos também possuem certificações CE, UL e CCC, incluindo os ventiladores centrífugos reversos UL.

Nossa equipe profissional de vendas está à disposição para sua consulta.