When using EC fans in industry, many things can change how good they perform. EC fans help to move air and cool down machines in factories. If the place around the fans get too hot, too cold, or full of dirt, it make harder for them to work properly This article look at what affect EC fans performance and how you can pick the best one for your need. We also talk about air quality and why it matter a lot. HangYan here to help you understand this better

Where to Get Good Quality EC Fans for Best Industrial Use

Finding right EC fans is very important for factory. You want fans that work good and last long time. HangYan have many kind of EC fans perfect for different works. When searching for high quality fans, think about what you need them to do. If your factory very hot, need fans that can cool things. If there lots of dust, need fans that handle that without break easy. Always check the material use to make the fans. Fans from strong stuff last longer and perform better in hard condition. Look for review from other people too, they tell you a lot about how good the fans is. Sometime visiting a factory who use these fans can show you real working. Don’t forget the warranty! Good warranty mean company trust their product. HangYan give warranties that make you feel safe. If problem happen, you can get help. It smart to talk with company about your special needs. They help choose best fan for your factory. This personal help make big different. Buying right fan not just pick random one. It about find perfect match for your factory need. HangYan ready to work with you

How Air Quality Affect Reliability of EC Fans

Air quality is super important for EC fans. When air clean, fans work better and last longer. But if much dust, smoke or other bad thing in air, it can damage the fans. Dust clog fan blades, make them hard to turn. When blades can’t spin easy, fan overheat and maybe break. In factory this mean machine stop, not good for business. HangYan know this problem and offer fans design to handle dirty air better. Some fans got filters that catch dust and dirt before reach blades. This keep fans clean and run smooth. Another thing is humidity. If air very wet, it can cause rust on fans, specially if not made from rust-proof material. You need choose fans that can take the humidity in your factory. HangYan fans built to resist moisture, so they keep working even in tough place. So pay attention to air quality in factory. Clean air mean happy fan, happy fan mean better work place. With right choice, your EC fans from HangYan can give good performance for many years

How to Pick Right EC Fans for Different Industrial Condition

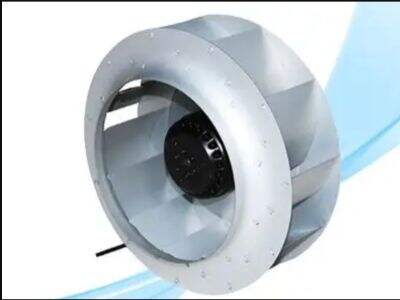

When choose EC fans for various industrial condition, important to know the environment where fans will use. EC fans mean Electronically Commutated fans, they popular because save energy and quiet. But not all EC fans same. Different industry have different need. For example, if you in factory with lots dust or dirt, need fan that can handle that. Look for fans with protect feature like filters to keep fan clean and work well. If your work have high temperature, like bakery or metal factory, choose fans from material that stand heat. HangYan offer variety EC fans for different condition, so you find one fit perfect. Also essential think about fan size. Too small fan not move enough air, too big one use too much power. Make sure calculate airflow need for your space. This help find right size. Also think about noise. In quiet place like hospital or office, want fan less noisy. HangYan have model design to be quiet but still strong. Finally, consider how easy install and use fan. Want simple setup and easy control. By keep these thing in mind, you can choose right EC fan for industrial condition, make workspace comfortable and efficient

What Maintenance Practice Improve EC Fan Performance in Hard Environment

Maintaining EC fans very important, especially in tough place. When fans use in area with much dust, moisture or heat, they wear faster if not care good. One best way keep your HangYan EC fans run well is clean regular. Dust and dirt build up on blades and inside motor, make fan work harder. This extra work lead to more energy use and damage over time. To clean, turn off fan and unplug. Use soft cloth or brush remove dust careful from blades and other part. For fans in humid place, check rust or corrosion. If see rust, clean it and put protective coat to stop more damage. Another important is check electrical connection Sometime wire loose or fray, affect fan work. Inspect wiring regular to make sure secure. Also, lubricating moving part can help fan run smooth. HangYan fans design low maintenance, but little oil go long way. Finally, always watch fan performance. If notice strange noise or less air move, maybe need deeper check. By follow these maintenance, you can improve performance of EC fans even in challenging environment

How to Spot and Fix Common EC Fan Problem in Industry

Sometime EC fans not work as good, important know how identify and solve problem. One common is unusual noise from fan. If hear grinding or rattling, maybe something wrong. First check if debris stuck in fan. Turn off and look for object cause noise. If clear, maybe motor or bearing problem. Then you may need call technician. Another problem is less airflow. If fan not move air like before, check filters. Clogged filter block air and reduce performance. Clean or replace filter regular to keep good. Sometime power supply issue. Make sure fan plugged and no blown fuse. If fan not turn on, check connection. Loose or damage wire can stop it. Lastly, temperature affect performance too. If too hot or cold, fan maybe not efficient. HangYan fans design for wide temperature, but in extreme condition check specification. By know these common problem and act fast, you can keep EC fans run smooth in any industrial place

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

BN

BN

KK

KK

UZ

UZ

XH

XH

/images/share.png)