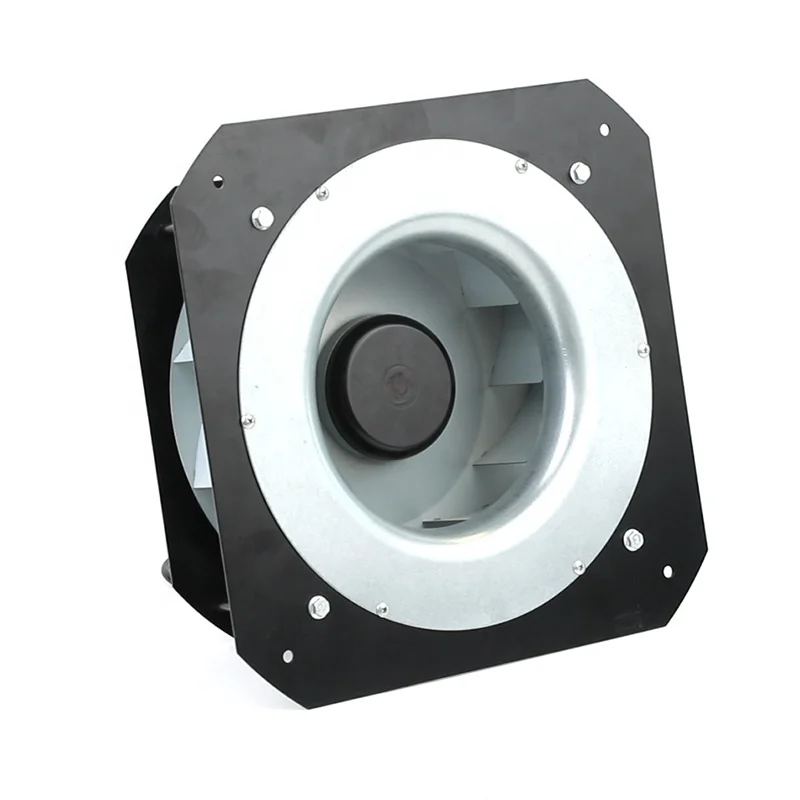

In a number of industries, high pressure centrifugal fans have become very common due to their superb capability in moving airstream against sharp static pressures. Its durable design has made it a popular across numerous industrial applications ranging from chemical processing to paper production and power generation, HVAC systems as well.

Greater efficiency than the traditional fans: One of the essential benefits that high pressure centrifugal blowers have is there higher performance.tokens. Propeller fans are good at low pressures, whereas centrifugal fan offers better high pressure performance while maintaining higher velocity of air flow. More air volume can be achieved without increasing fan drum speed; hence, using less power on high pressure centrifugal fans. They are also able to work under different conditions like extreme temperatures and corrodible, or explosion proof environments.

High pressure centrifugal fans have become incredibly popular in modern day HVAC systems, and for good reason--they offer a great combination of efficiency, reliability, and quiet operation. They deliver a consistent flow of air, allowing for even temperature control and uniform distribution across the building. When comparing centrifugal fans to traditional axial-type fan types, the latter will often achieve better pressures at lower airflow rates than a vorticed range of static pressure that may require efficient handling.

One other benefit of using High pressure Centrifugal fan in HVAC systems is that these fans are really quite. Due to their unique construction design, works at low noise levels unlike other types of fans making axial flow fan a great option for installations with limited space that must maintain lower sound levels.

Where High Pressure Centrifugal Fans Are Essential for Dust Collection and Material Handling

High Pressure Centrifugal Fans are used in applications such as Dust collection, pneumatic conveying and material handling where large volume of air is to be moved at high pressure. Waves fans help maintain steady airflow to keep airborne pollutants away from production processes. They are also worth considering for carrying in bulk materials such as powders, granules and pellets

Due to the nature of air flow and material movement in dust collection systems, as well as for most other process fans used in pneumatic conveying applications, centrifugal fan designs must be tailored/optimized at an engineering level specifically designed around or with a general understanding towards your application. One of which might be specified-fan wear, corrosion or abrasion resistant components and the use specialized materials. Other than that, high pressure centrifugal fans can be designed for hot temperature and pressure conditions along with being efficient.

High Pressure Centrifugal Fans are trustworthy to fortifying airflow and operation efficiency in diverse manufacturing operations. These fans can work with a variety of gases, vapors and corrosive chemical fumes that are generated in the process enclosure. As they can handle extremely high pressures and maintain stable airflow rates, many plants rely on them when trying to improve the efficiency of their industrial processes.

In addition to that, large pressure cast aluminum construction centrifugal fans have also been specially designed for cooling and ventilation needs in industrial factories. This ensures cleaner and cooler air in the production area, resulting in increased productivity.

High Pressure Centrifugal Fans operate in critical environments where reliability is essential, such as petrochemical plants, refineries & power generation. In these scenarios, a failure of any equipment can result in results ranging from damage to personal injury and even death or environmental damage/loss of property.

Safety is paramount throughout the design of these fans, with multiple safety features built in, such as thermal overload protection; vibration monitoring and surge protectors for complete peace-of-mind. They are also quite expensive and require periodic maintenance === They can even cost a whole lot of penny as well as need much frequent servicing to keep them in good order. In addition, most centrifugal fans are built with high-pressure applications in mind and meet industry standards for quality, performance ad safety.

The innovation of high pressure centrifugal fans has transformed many industrial processes by producing a huge amount of air at very low energy costs. Which includes heating and cooling, dust collection, material handling etc due to their high efficiency, low noise operation along with great safety features. The Most important thing is that you make correct customization of the fan and also provide a regular maintenance to these fans so as to work best for long whether it be industrial hvls ceiling fan.

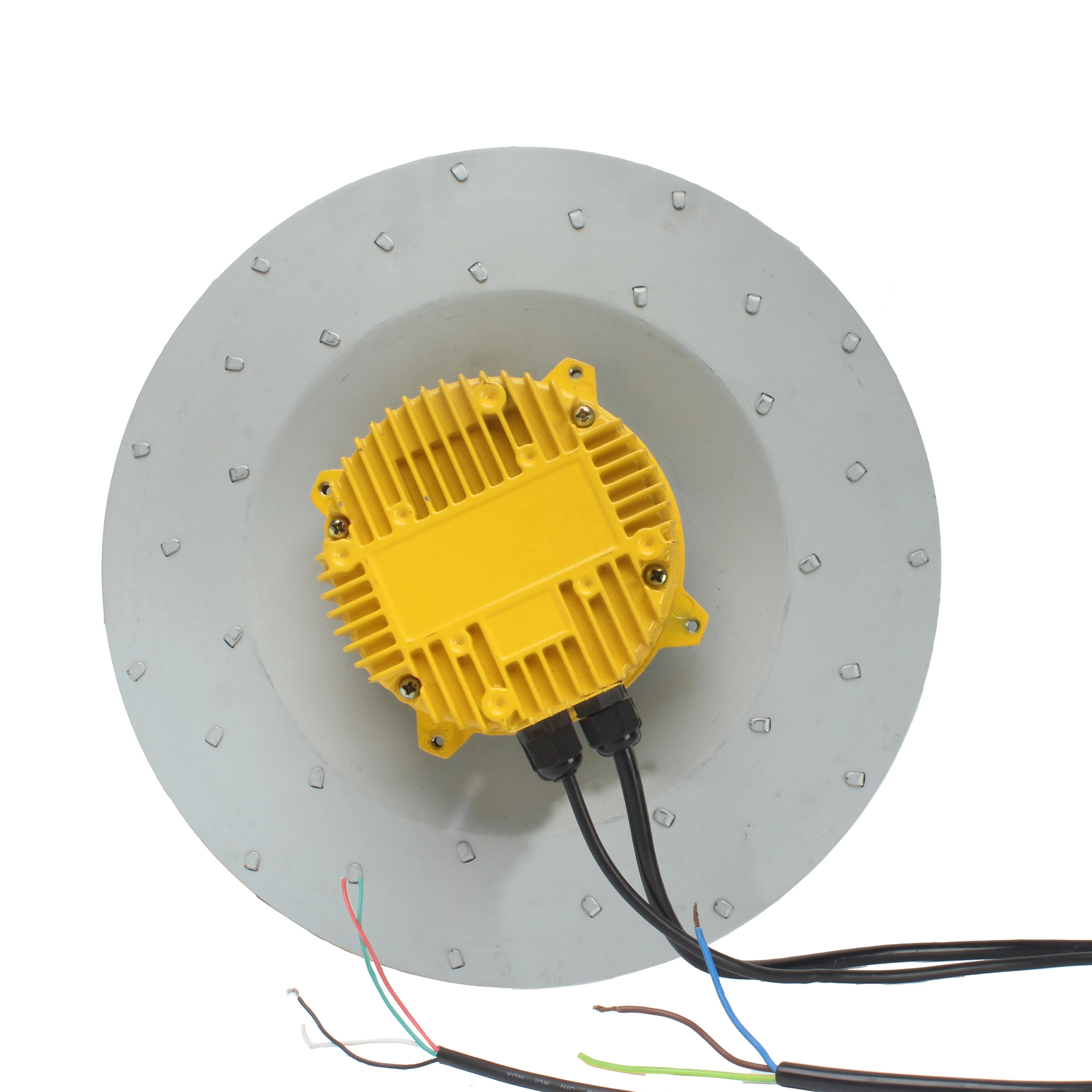

a professional manufacturer, are in a very good position supply most grades of fans and high pressure centrifugal fanaffordable prices, and for timely delivery. provide AC fans, EC motors and DC fans. New products are being designed. company also cooperates together with college technology experts in order to design new fans.

have an experienced R D department with years knowledge. follow strict high pressure centrifugal fanguidelines quality control. production process is conformity with ISO9001, and products have achieved CE certification and UL certification. We also have CCC certification.In addition, we will increase more certifications to meet the demands of our customers in the further.

are in a position take orders from customers samples indicating specifications, design packaging requirements. we provide best after sale service. As always, we will be true our fundamental business concept: Integrity Quality, Innovation, and Win-Win". We continue to formulate a "Hangyan" brand operation strategy,and form service high pressure centrifugal fanof excellent cost-effective.We collaborate with our customers through our practical approach and sincerity work together to build a better future.

company was established in 1996. production plant area of company covers 30000 square high pressure centrifugal fanand equipped with eleven workshops.We a leading manufacturer that is researching and developing different types of externalrotor fans as well as DC motors.We have more than 100 employees , more than six production lines and more than 25 years of export experience.

Our professional sales team are waiting for your consultation.