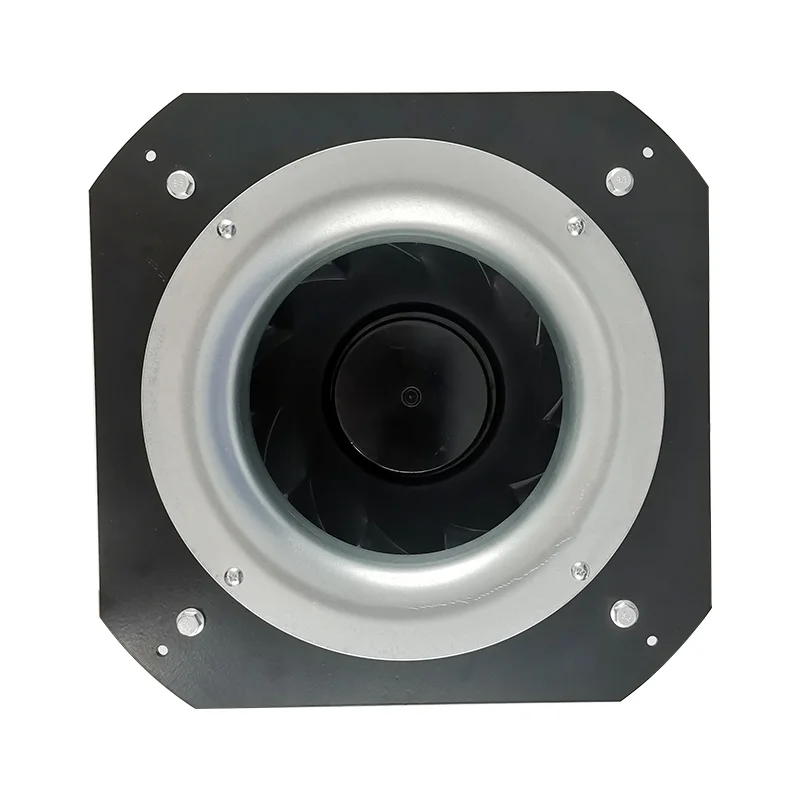

Backward Centrifugal Fan is a special category of the fan that can be easily found in most air handling systems. Thanks to its curved blades (as oppose to the traditional ones) air flows in a circular motion, ultimately pushing this same flow away from the center of it. It allows the fan to operate efficiently and reliably, hence it is widely used across different applications that require air movement.

When it comes to backward centrifugal fan, one of the major benefits is its efficiency. These fans have been engineered to consume significantly less energy and deliver the same amount of air flow as traditional fan design. Energy savings translate to both cost dollar reductions and a decrease the use of energy resources which improves the green badge value.

They are the best then if their efficiency is discussed and even when about reliability backward centrifugal fans top the charts of all in general. Manufactured for strength and longevity, these fans are made of heavy-duty materials so they would operate consistently in air handling systems throughout different applications.

A very important difference between the forward and backward centrifugal fans is that of air flow direction. Forward fans move air through a linear path, whereas backward-flowing models circulate the airflow in circles that project outwards from the center. The airflow design, which is backwards when using centrifugal fans can circulate air more efficiently in a room.

Another important difference between these fan types is their blade design. Forward fans usually contain direct blades, whereas backward fans include the bent-out wide blades which are designed for high airflow efficiency. This design feature allows backward centrifugal fans to operate more efficiently, and thus improve air circulation in the compiled handling units.

Any backward centrifugal fan must be kept in the good working condition and to happen so certain precautions need there follow up. It is imperative that the fan be cleaned regularly to avoid blockage of debris, which would otherwise lead to poor airflow and efficacy. Installation and balance are also extremely important factors in reducing fan-related fluctuations that could reduce the life of a VSD fan.

Moreover, every time they are mulling over an existing fan system upgrade as the case may be; it will very likely see through a transition to backward centrifugal fans. Especially if the existing fan is old, replacing with a high-efficiency model such as reverse centrifugal can save significant energy. In addition, the characteristic high air-flow requirements of numerous pneumatic air handling systems ensure that backward curved centrifugal fans have a competitive edge when it comes to improving performance and reliability.

ConclusionBackward type Centrifugal Fans play a significant role in ensuring the best ventilation Air Handling systems can offer-efficient, reliable solutions for moving air. Through analyzing the mechanics of these fans, comparing different types and maintaining procedures, it is possible to maximize life cycle and operation from your chosen fan system. Upgrading to a Type BC backward centrifugal fan can be an effective way to improve overall performance, long-term energy savings and operation process.

Our R D team has years of backward centrifugal fanis high-quality. We adhere to the strictest standards quality assurance. production process is in compliance with ISO9001:2015. Also, products have been certified with CE certification and UL certification. We also have CCC certification.In the meantime, we will increase more certification as customers' requirements in further.

are a professional manufacturer, we can supply motors and fans various types at competitive costs. backward centrifugal faninclude AC fans, EC fans, DC motors, new products are being developed. Our company also works with experts from colleges in order to develop innovative fans.

company was established 1996. The backward centrifugal fanplant area of company covers 30000 square meters and is equipped with eleven workshops.We are reputable manufacturer that researching and developing various kinds of externalrotor fan as well as DC motors.We have more than 100 employees, more than six production lines, and more than 25 years of export experience.

are in a position take orders from customers samples indicating specifications, design packaging requirements. we provide best after sale service. As always, we will be true our fundamental business concept: Integrity Quality, Innovation, and Win-Win". We continue to formulate a "Hangyan" brand operation strategy,and form service backward centrifugal fanof excellent cost-effective.We collaborate with our customers through our practical approach and sincerity work together to build a better future.

Our professional sales team are waiting for your consultation.